Timber and aluminium composite windows provide a perfect balance between the natural beauty of timber on the inside, and the high performance and weather resistance of aluminium on the outside.

Sustainably sourced timber with full PEFC or FSC® accreditation and aluminium with a high percentage of recycled raw materials can also help with the environmental credentials of the project.

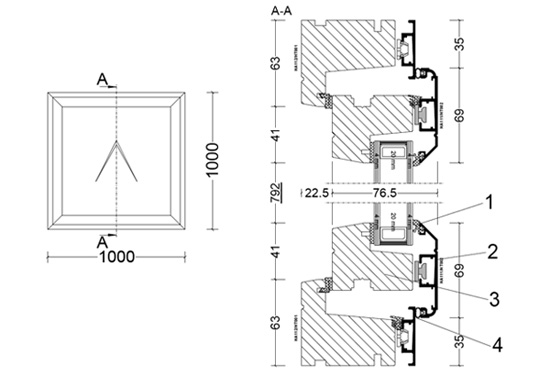

Below we look at the elements of the system that make composite windows so effective.

1 – Glazing gasket to ensure a neat, clean, dry glazing system, designed to maintain pressure on the glass. When used in conjunction with the security tape behind, together with correct hardware, it ensures maximum security as tested to the requirements of BS7950.

2 – Aluminium cassette fixed to the front of the sections with plastic clips. The aluminium is extruded from predominantly recycled aluminium. Finishes are available in a wide variety of polyester powder coat colours, or anodised if so desired.

The gap created by the use of these clips enhances thermal properties and provides unobstructed routes for drainage. Window systems are also tested to BS6375 for weather resistance.

3 – Sustainably sourced engineered timber profiles, jointed using 45 degree mitre cuts ensuring closed cell technology, ensuring no water ingress to end of machined timber.

4 – Bubble gasket as weather seal, ensuring a neat, clean, closure against frame element.

To find out more about the use of composite window systems read the case study.